Until recently, terminating cross-passage membranes to TBM segments had been one of the unsolved mysteries of tunnelling. Thanks to recent innovations in gaskets and pressure terminations, all hydrostatic forces can be resisted to ensure they meet the ‘no damp patches’ specification.

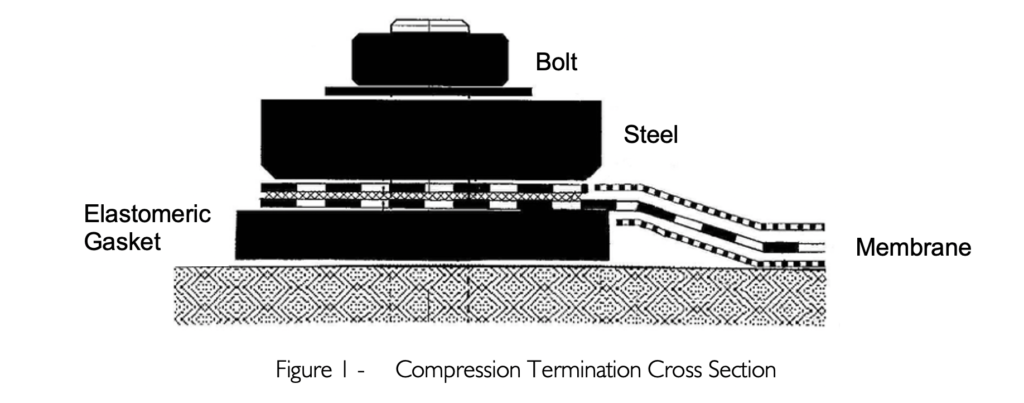

The most challenging part of any cross-passage termination is ensuring the membrane connects and seals to the TBM gaskets successfully. This is often difficult to do, due to:

(a) The gaskets being damaged during cutting of the TBM segments.

(b) The termination occurring on the rear face of the segment (rather than the cut face).

(c) The TBM gaskets being located too close to the rear face to allow fixing of the membrane termination seal at that location.

If any of these issues are overlooked, the termination seal will not be continuous and water may travel over and under the seals and leak freely into the tunnel.

How to ensure the compression gasket will resist natural groundwater pressure.

Ensuring a continuous seal between the TBM segment gaskets and the membrane is critical to preventing water infiltration.

The TBM gasket is embedded within the segment in which multiple connection configurations can be present on a single cross-passage. This is dependent on the location of the cuts for the opening and the position of the membrane termination. As the exact position of the opening cut is quite random, (in terms of the TBM ring and segment positions), only a small amount of pre-planning can be carried out precisely.

ASME Boiler and Pressure Vessel Code (2017) determines that leakage will occur where the hydrostatic forces are equal to the internal pressure in the gasket, therefore a factor of safety is required. This is set as a minimum of 2x for waterproofing applications. However, typically seals can easily be designed for 100m of water head when as little as 20m is being resisted providing a much higher factor of safety.

ASME Boiler and Pressure Vessel Code (2017) determines that leakage will occur where the hydrostatic forces are equal to the internal pressure in the gasket, therefore a factor of safety is required. This is set as a minimum of 2x for waterproofing applications. However, typically seals can easily be designed for 100m of water head when as little as 20m is being resisted providing a much higher factor of safety.

The most accurate method of measuring the gasket pressure on site is by reading the compressed thickness.

For this application, we refer to the Kunz and Studer formula where the modulus of elasticity in compression is determined by the Shore A hardness and the percentage compression.

This principle of pressure terminations is applied in most cases where membrane penetrations and terminations must be formed, and water pressure is likely to be present. These terminations have a track record in Australia of performance at up to 80m of water head without leakage.

Note: In-house, testing has also been conducted to confirm theoretical results

Summary

Terminating cross-passage membranes to TBM segments had previously been one of the unsolved mysteries of tunnelling. We’ve developed this gasket solution which is now being adopted around the world in underground environments.

Learn more about Our Products, our expert Waterproofing Technicians or cross passage terminations, through the links provided.