With projects now spanning from New Zealand to Singapore, BluSeal AKS has quickly become the highest industry standard for concrete protection. As a relatively new technology in an industry that upholds the old fashion way of doing things, BluSeal AKS has anchored its way into new and existing structures across Australasia.

HOW IT ALL BEGAN…

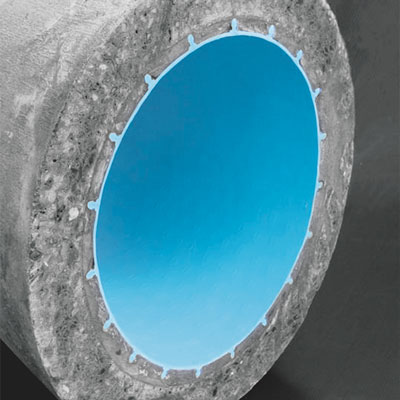

Bluey saw a need for an innovative product to rival the faulty epoxy coatings which were the industry’s only option at the time. When BluSeal AKS was introduced to the Australian public, the membrane was marvelled at due to its extremely low puncture, tear resistance and tensile properties.

Since then, the Bluey Team has now installed more than 500,000sqm of BluSeal AKS. That’s more than 600 million individual anchors.

THIOBACILLUS CONCRETIVOURUS

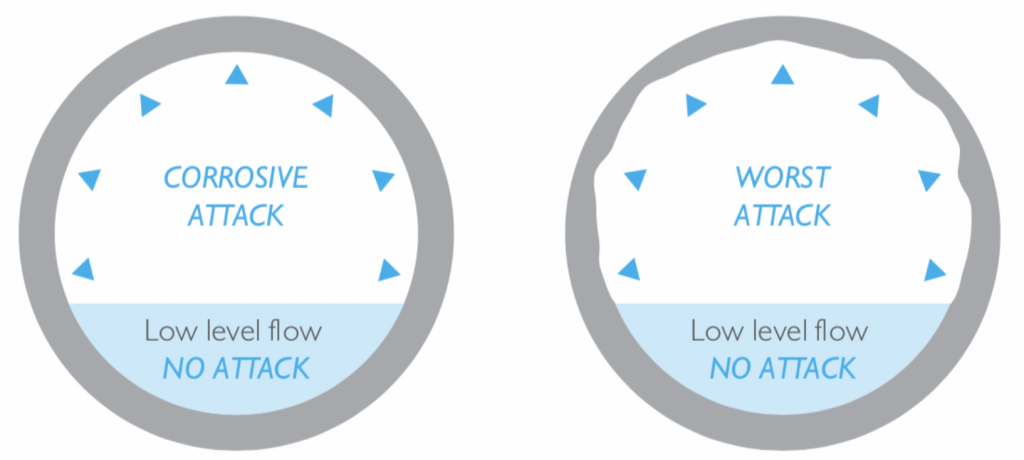

A common misconception in the industry is that the greatest corrosive attack to membranes occurs below the water level. This is not the case. In-fact, the worst chemical attack in these environments occurs above the water level, as an aggressive bacteria; Thiobacillus Concretivourus. This airborne bacteria circulates in sewer treatment plants, pump stations and manholes and uses sulphur as a primary energy source which breaks down concrete and epoxies over time.

Below is a cross-sectional diagram of the effects of Thiobacillus Concretivourus.

What has made BluSeal AKS stand out from the pack for the past 15 years is its impressive durability and resistance to chemically aggressive environments. BluSeal AKS’ durability stems from the use of highest quality HDPE resins which have been proven to have the best possible resistance to acidic attack. This makes the membrane more sulphur resistant, meaning a design life of more than 100 years.

To ensure bacteria and corrosion do not affect the longevity of your next project, get in touch with Bluey on 1300 0 BLUEY.