When it comes to the success of tunnelling ventures, the rock bolts involved play an essential role. They are of vital importance to structural integrity and stability. Knowing how crucial this is to any project, Bluey has developed two new products, which feature the latest innovations in bolting technology.

Part of Bluey Technologies’ BluGeo line, these new low-profile bolts provide numerous benefits to any project, including cost and productivity savings, a lower environmental impact and a higher-quality end result.

Advances in low-profile bolting

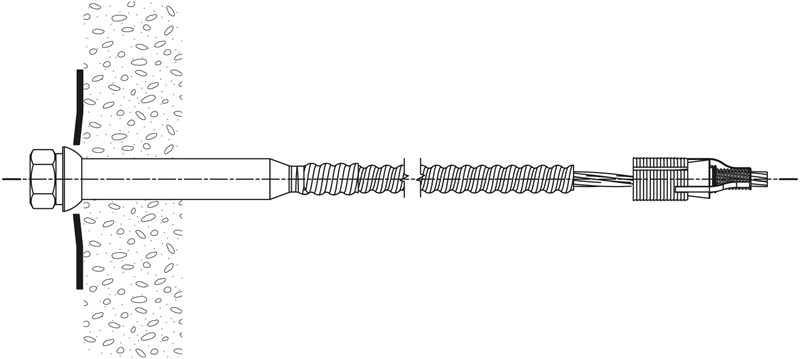

Bluey Technologies’ low-profile bolts feature a completely new design of how a nut fits onto the end of the bolt. With traditional rock bolts, there is a section of about 150 millimeters sticking out of a hole – this must then be covered by a minimum 50 mm of shotcrete. This protective layer is essential in preventing corrosion of the nut and bolt. On a tunnelling project with bolts in a 1-metre grid, this adds up to a significant amount of coverage.

The LP bolts reimagine the way a nut fits onto a bolt.

BluGeo LP Bolts, however, don’t stick out of the hole; the nut actually sits inside the hole, resulting in a small dome about the size of a 50-cent coin sitting on the surface. This can be covered with significantly less shotcrete – which has immediate benefits for contractors and engineers.

For added convenience, the bolts have testing capabilities incorporated into the nut; this makes testing significantly easier as the nut and plate do not have to be removed.

Introducing the new bolts

These advances in bolting technology have led to the development of two new additions to Bluey Technologies’ BluGeo line – the LP Rock Bolt and CF Rock Bolt. Designed for both temporary and permanent applications, these bolts feature double corrosion protection. This durability ensures that the LP bolts can meet the needs of any project.

Not all tunnelling projects have the same requirements, and the low-profile bolts take this into account. They are available in three compositions:

- Black steel: suitable for temporary applications.

- Galvanised steel: a 50-year design life.

- Stainless steel: a 100-year design life.

This ensures that any project – whether a new tunnel, retrofit or renovation – can be outfitted with the appropriate bolts at the right cost.

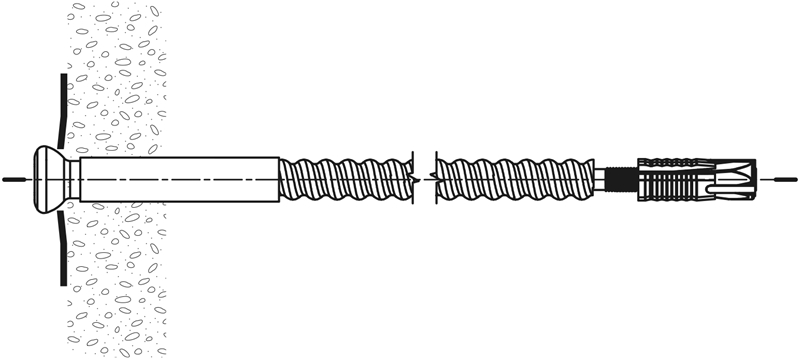

Bluey Technologies’ CF Rock Bolt features a time-saving, automated installation process.

Bluey Technologies’ CF Rock Bolt features a time-saving, automated installation process.Installation is simple with the cable bolts – a new pendulum system means that holes can be drilled and the bolts installed and grouted without the need for manual handling.

Since it has a flexible design, the cable bolt is not restricted by the internal height of a tunnel; it comes in varying lengths to suit the project, The LP Rock Bolt, on the other hand, is available in lengths up to six metres.

Additionally, there are two weight capacities for the CF Rock Bolts – 30 and 60 tonnes. As different ground conditions can necessitate different strength requirements for cable bolts, these options ensure that the CF Rock Bolt can meet the needs of any job site.

Low-profile bolts, high-profile advantages

The BluGeo LP Rock Bolts offer a number of distinct benefits, thanks to their design. Requiring less shotcrete to provide a layer of coverage, the low-profile bolts provide serious savings in cost by drastically lowering the amount of concrete needed, as well as the amount of time needed for installation.

This has carry-over benefits through a reduction in transportation, working hours and storage needs. A lowered need for shotcrete also provides environmental benefits by eliminating the carbon emissions that would result from the production and shipping of that shotcrete.

With their low-profile, tailless design, the bolts also provide aesthetic benefits for any project. The small, domed finish is beneficial for road architects who wish to incorporate visual appeal into their infrastructure designs – a growing trend in urban civil engineering.

With its low-profile design, Bluey’ Technologies’ LP Rock Bolt provides improvements in safety and stability.

With its low-profile design, Bluey’ Technologies’ LP Rock Bolt provides improvements in safety and stability.Thanks to their low-profile design – and availability in stainless steel – Bluey Technologies’ new bolt products also lead to improvements in fire safety for tunnels. As the nut grips the bar within the hole instead of on the surface, it is protected against temperature rises inside a tunnel. In addition, the stainless steel bolts are more resistant to higher temperatures – other steel softens and loses its strength at a certain point. Since tunnel fires can reach over 1,000 degrees Celsius, heat-resistance is a crucial element of safety.

A successful tunnelling venture takes more than just the right tools and equipment; it requires the know-how born of years of experience. Bluey Technologies’ engineers are able to lend their expertise to any civil engineering project through support, training and advice. For more information, contact Bluey today.