It’s been two years since China stopped importing the glass that Australians put in their yellow bins.

Up to the first half of 2018, China annually imported more than 30 million metric tonnes of waste from all over the world. From July onward, however, the Chinese Government decided that they would no longer accept “foreign garbage” and focus on recycling domestically.

The ban threw a spanner in the works for many recycling plant operators across Australia. For a lucky few, this change brought new opportunities. For most, the ban resulted in expensive and unforeseen costs, like renegotiating storage contracts at higher rates to destroy the waste. For others, their stock has been left forgotten in storage yards, including the recycled glass piles, still growing in size across Australia.

When this news broke in 2018, we were purchasing thousands of tonnes of sand, being mined from riverbeds around the country. We understood that glass is made from sand, so we were keen to know if the glass could be crushed and repurposed to replace the environmental destruction that the sand mining was creating and, at the same time, possibly solve the recycled glass crisis.

This wasn’t the first time that glass had been looked to as a replacement for sand. Decades earlier, standard cement (OPC) and glass was proposed, however the testing showed that when applied together, the cement would attack and degrade the glass, resulting in the fast deterioration of concrete structures. This meant that the alternative material was abandoned, long before our time.

However, recognising this waste as a material of potential value, we at Bluey began developing a cement binder system, which doesn’t rely on OPC to be an effective cement. After 18 months of testing, this new binder reopened the possibility of using glass as the aggregate for the sewer liner. We knew instinctively that glass was acid and chemical resistant so why wouldn’t it work in our new product.

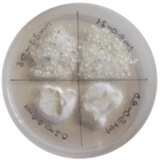

After testing various types of glass from recycling plants across the country, BluCem ZeoGlass (ZeoGlass) was born. ZeoGlass is an acid-resistant, structural shotcrete, designed for re-lining Australia’s deteriorating sewer networks. Glass is the perfect material for Australia’s harsh, acidic sewer environments, being totally resistant to corrosion.

After testing various types of glass from recycling plants across the country, BluCem ZeoGlass (ZeoGlass) was born. ZeoGlass is an acid-resistant, structural shotcrete, designed for re-lining Australia’s deteriorating sewer networks. Glass is the perfect material for Australia’s harsh, acidic sewer environments, being totally resistant to corrosion.

Current cementitious products used for sewer rehabilitation in Australia are imported from Europe at great expense to the local economy. Using local recycled materials to solve a growing national problem, we began working with Sydney Water to develop the locally manufactured alternative.

Based upon current usage of alternative imported products, Sydney Water’s adoption of ZeoGlass has the potential to exhaust all existing glass stockpiles in NSW within two years, providing relief and revenue for our Aussie glass recyclers.

- ZeoGlass utilises 3mm recycled glass aggregates

- ZeoGlass uses a proprietary binder system; it’s very low in alkalinity and does not induce any form of Alkali-Silica Reaction or Alkali Aggregate Reaction.

- ZeoGlass is made up of more than 60% recycled products, including the compostable packaging, which breaks down to soil in less than 100 days.

We’ve strived to develop a product that’s a leader in our industry. ZeoGlass has minimal water demand meaning very low water-cement ratios can be achieved with dry spraying whilst still ensuring proper cement binder hydration and compaction. This greatly enhances the durability of the cured product. In addition, along with the recycled glass, ZeoGlass is made up of a wide range of by-product materials including slags, fly ash and hydrothermal silica deposits, further reducing our environmental footprint.

With standards and approvals being accepted in 2019, BluCem ZeoGlass is now starting to be used on sites around Australia.

To learn more about BluCem ZeoGlass and the applications for use, contact us at 1300 0 BLUEY or email bluey@bluey.com.au