Going against the status-quo has always been the Bluey way. We’ve worked hard over the years to find ways for Bluey and our partners to get ahead of the competition, by not competing with it. Whether it’s a new field of engineering or the development of a new product, we are always drawn to doing things a little differently to help our customers. This mantra is not dissimilar to the popular book, Blue Ocean Strategy by W. Chan Kim & Renee Mauborgne.

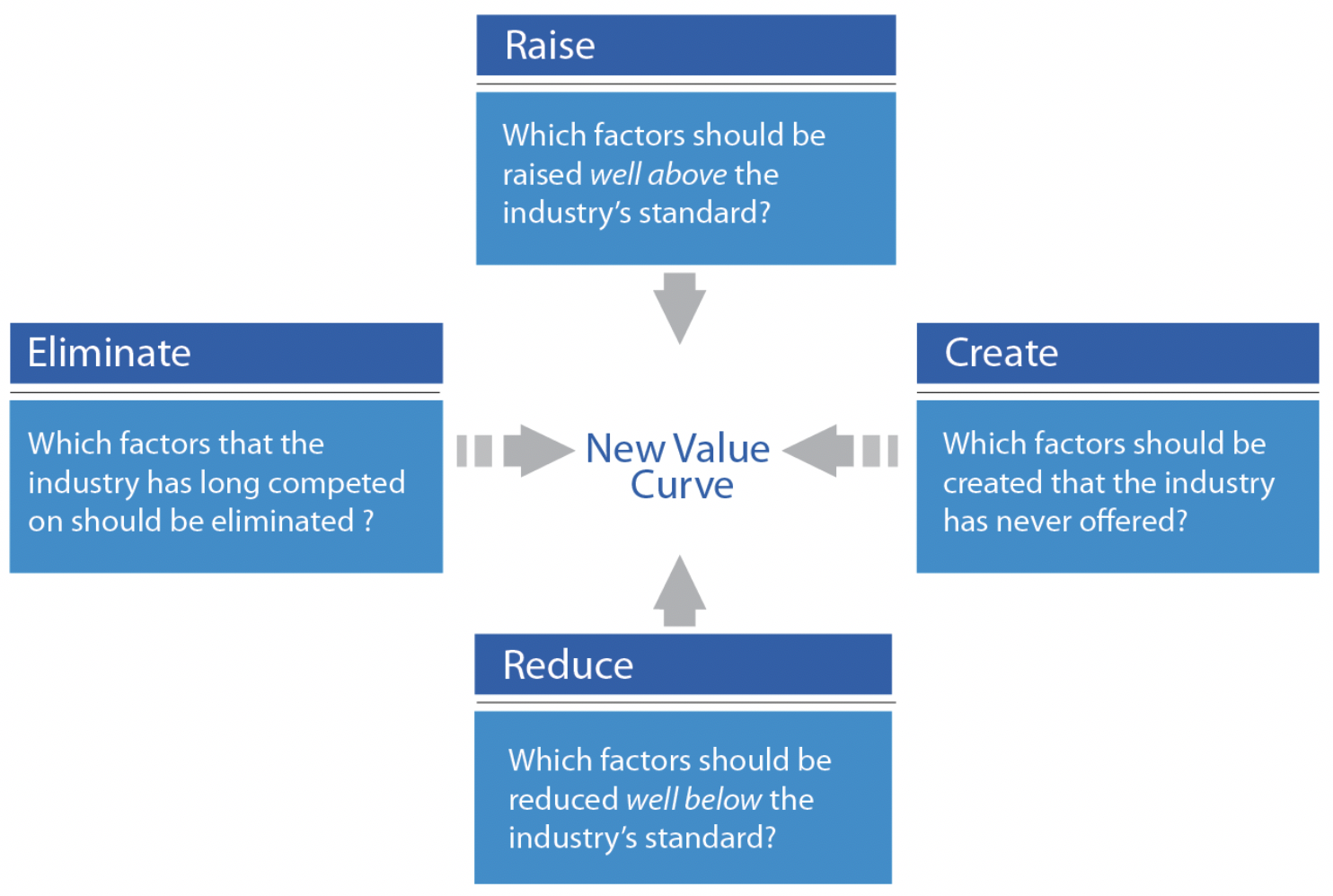

Known by many in business, the book explores the “Four Actions Framework” which details how to create a ‘blue ocean’ of new customers, rather than swimming with the sharks.

Utilising the Four Actions Framework brought Bluey & FiReP together in 2013. (Pictured right, a clean-shaven Daniel Bosco)

THE FOUR ACTIONS FRAMEWORK

Eliminate: Which factors that the industry has long competed on should be eliminated?

Currently, the strength of steel is the metric to determine the overall quality of many products in the civil industry. When taking a step back to question steel as the measure of strength, Bluey searched for materials of higher strength that the industry was not competing on.

Following discussions, Bluey partnered with FiReP to produce Glass-fibre Reinforced Polymer (GRP) bar. The new product not only introduced the civil industry to a lightweight, higher strength alternative but also provided FiReP with a blue ocean of new customers, by leveraging Bluey’s presence in Australia, New Zealand and South East Asia.

Reduce: Which factors should be reduced well below the industry standard?

When dealing with steel in civil applications, rust and acidic attack can result in a weakened structure, concrete spalling or large-scale repairs. To counter this, double corrosion protection is required to protect the steel. This results in larger holes being drilled to fit extra sheathing, creating an on flow of additional costs to the project. To reduce this factor below the industry’s accepted standard, Bluey sought out a material that

does not require double corrosion protection. As GRP is a corrosion-resistant polymer, it does not require the same large hole as regular steel, reducing the hole size by up to 50%. Meaning 50% less drilling (image right), less earth removal and reduced transport costs. The use of GRP in ground anchors and soil nails created new demand of customers for FiReP and Bluey as word of GRP products continues to be adopted as best practise throughout the industry.

does not require double corrosion protection. As GRP is a corrosion-resistant polymer, it does not require the same large hole as regular steel, reducing the hole size by up to 50%. Meaning 50% less drilling (image right), less earth removal and reduced transport costs. The use of GRP in ground anchors and soil nails created new demand of customers for FiReP and Bluey as word of GRP products continues to be adopted as best practise throughout the industry.

Raise: Which factors should be raised well above the industry standard?

Using steel as the measure of strength is completely relative. Compared to wood, yes, steel is stronger. To GRP, on the other hand, it’s not. Bluey wanted to raise the industry’s understanding of the potential of soil nails and ground anchors in civil applications. Using GRP almost doubles the tensile strength (800-1000N/mm2) compared to steel (600N/mm2) in these applications.

The other low standard the industry has accepted without question is the weight of soil nails and anchors. The images below show the labour required to move steel (left) versus GRP (right) around site. This is not to be understated, the reduced labour costs are dramatic and obvious.

Create: Which factors should be created that the industry has never offered?

One of the largest challenges for specifiers and installers is finding products from different suppliers that work seamlessly when installed. When developing new partnerships, the new products being introduced must not only be a breakthrough product on their own, but must fit the specifications of other products across the Bluey range. This allows our partner’s products to be used with the Bluey range, providing specifiers with fewer headaches and costs on projects both large and small.

An example of this is FiReP’s GRP bar. The glass-fibre reinforced polymer has been designed to work perfectly with our wide range of BluCem grout products such as BluCem HS200, HS200A and HS400. This has resulted in customers who were exclusively using the BluCem range of cements, grouts and repair mortars the ability to use the BluGeo GRP range for applications such as slope stabilisation, ground anchoring, tunnelling and formworks.

To learn more about how we’re developing products, BluGeo GRP bars or other products that have been designed with the Bluey range in mind, contact us on 1300 0 BLUEY or email bluey@bluey.com.au today.