In the world of concrete failure, the cause of the problem is not often visible, rather it is just a symptom of the real cause. Before any external faults show, stresses build up, internal chemical reactions may take place and unknown costs are already needed to repair the concealed failure. By the time it is visible, it could all be too late.

Each failure requires unique testing, product selection and application to restore the structure to its original state. Major failures used usually triggered by an external force, which then results in a domino effect of failures from imperfections in the concrete or flaws in the reinforcement.

Each failure requires unique testing, product selection and application to restore the structure to its original state. Major failures used usually triggered by an external force, which then results in a domino effect of failures from imperfections in the concrete or flaws in the reinforcement.

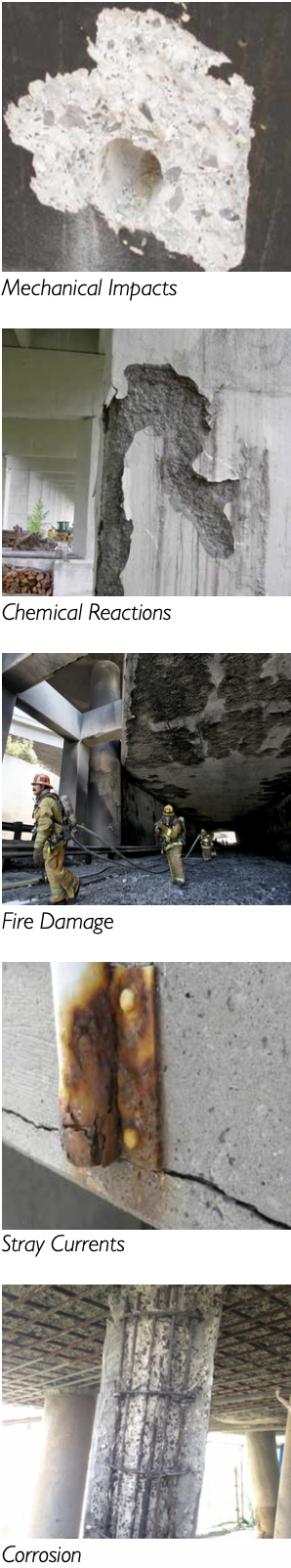

Bluey offers a wide range of products for concrete repairs, testing equipment as well as installation teams to restore a wide range of all concrete failures. Below we’ve listed the 5 most common concrete failures that we frequently repair and their causes.

1. MECHANICAL

Most mechanical failures occur because of physical impacts such as collisions. Vibrations, overloading and other movements can also result in cracking and loss of entire concrete sections.

2. CHEMICAL

Although an initial chemical reaction is required to create a reliable, load-bearing concrete, other chemical reactions such as ASR and contaminants from soil such as sulphates can weaken the cement matrix.

3. FIRE

The excessive heat generated from fires can alter the properties of concrete. When exposed to extreme temperatures, problems such as expansion and deterioration can occur.

4. STRAY CURRENTS

Stray electrical currents carrying high volts can often act as the catalyst for the corrosion of rebar from the inside. This can lead to spalling, otherwise known as ‘concrete cancer’.

5. CORROSION

When concrete fails to provide adequate protection from extremities such as road salts, seawater and chlorides, the steel rebar will corrode. Cracks, low cover, porosity and low alkalinity are also other causes of inadequate protection.

Concrete failure is a complex hazard. It is important to know what shortcoming is causing the defect prior to starting repair works. Bluey has a range of solutions and products including repair mortars, resins, injection chemicals and grouts to select from, to ensure the right product is used in the right application.

Before you begin repairs, we recommend that you speak to Bluey so that we can offer sound engineering advice, conduct testing of the concrete and help you select the right product to eliminate any chance of further failures.

Contact the team today at bluey@bluey.com.au or call 1300 0 BLUEY.