At the time it was Australia’s largest road infrastructure project. A 6.7km toll road featuring twin 5.1km tunnels connecting Brisbane’s CBD with the Northern Suburbs Airport Precinct. Since their completion in 2012, the tunnels and roadways are now part of a valuable Brisbane asset, assisting traffic flow and easing congestion.

At the time it was Australia’s largest road infrastructure project. A 6.7km toll road featuring twin 5.1km tunnels connecting Brisbane’s CBD with the Northern Suburbs Airport Precinct. Since their completion in 2012, the tunnels and roadways are now part of a valuable Brisbane asset, assisting traffic flow and easing congestion.

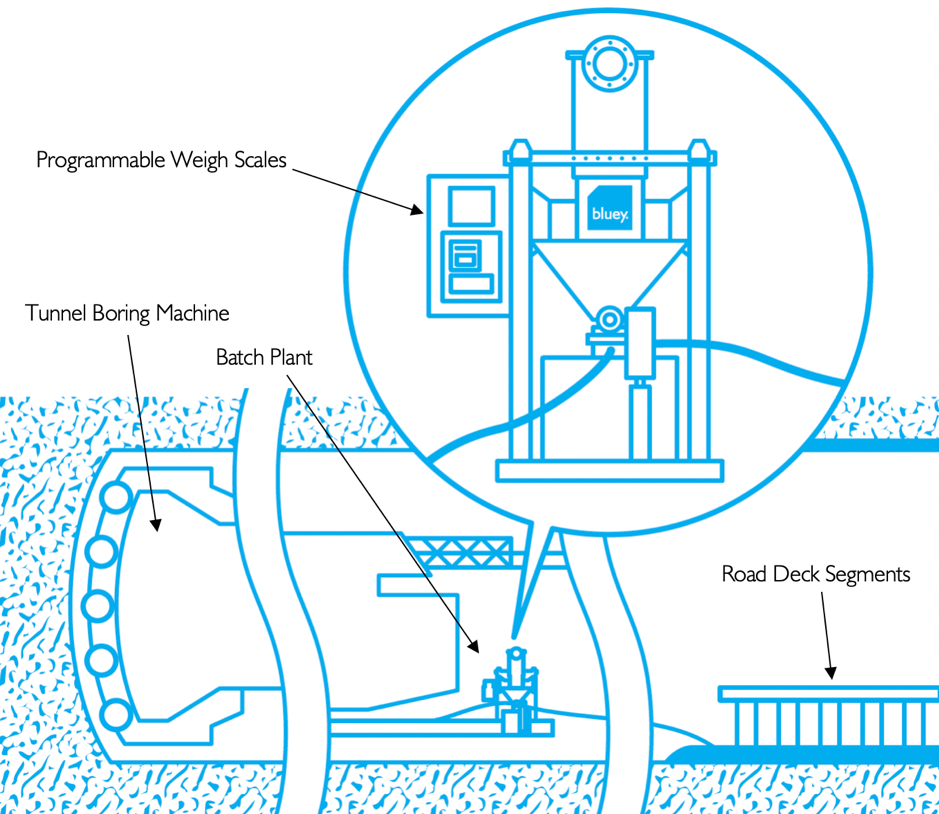

Upon starting the project, the contractor faced the challenge of a tight deadline. To meet the deadline, the precast road deck segments had to be grouted in place while the TBM was simultaneously boring through the ground 100m further along the tunnel. The roadway had to carry heavy vehicle traffic and deliver segment rings to the TBM, within 5 hours of grouting.

The solution that the engineers developed was simple and resourceful. The team designed and built a miniature batch plant with programmable weigh scales and grout mixer/pump which was attached to the back of each TBM. From there, the grout was pumped up to 100m through the tunnel to the road deck segments.

The grout production and delivery idea were sound, but a grout was needed which could not only meet the strength requirements but also had to be highly flowable and be able to be pumped through the 100m pipe into very narrow gaps. The answer was BluCemHE80.

Benefits of BluCem HE80:

- Ultra-rapid strength gain – Capable of taking the weight of heavy vehicles and segment rings to the TBM, within 5 hours of grouting.

- Highly flowable and pumpable – This allowed the grout to be pumped 100m and into gaps several millimetres wide.

- Dual shrinkage control – Ensuring the grout remained stable even when pumped into 20mm gaps.

- High strength – Essential to take the weight of vehicles consistently once the road was opened.

- 100-year durability – Meeting the specifications of the tunnel’s design life.

- BluCem HE80 was successfully pumped from the TBM to the roadway deck into gaps between 20mm to 90mm for the entire 5.1km.

The illustration below shows the setup.

In just three and a half years, (November 2008 to July 2012) the project was open to the public. The JV benefited from the BluCem HE80 technology as the tunnelling program and roadway construction was completed before the agreed deadline. Contractors operated the batching facilities on each TBM in a safe, efficient and timely manner.

To learn more about BluCem HE80 and the project solutions we’ve developed in the past, visit the links below:

– Product Information: https://www.bluey.com.au/products/blucem-he80

– Technical Datasheet: https://www.bluey.com.au/wp-content/uploads/2012/02/BC-45

– Melbourne Airport Project Report: https://www.bluey.com.au/project/blucem-he80

– HE80 Underslab grouting on the M1 Motorway: https://www.bluey.com.au/civil-engineering