Successful shrinkage compensation coincides with each phase of shrinkage. In other words, the magnitude of expansion and the timing of occurrence should be equivalent to the predicted shrinkage for each stage of the grout or concrete’s life. To achieve shrinkage compensation, we use a variety of techniques and products.

1. Reducing Shrinkage

Lowering the water/cement ratio

A common method to achieve a reduction in shrinkage is by lowering the water/cement ratio through the application of water-reducing agents such as our BluCem Add Flow – Superplasticiser. Although water may make a grout/concrete more fluid, the increased water will result in other issues such as high bleed, segregation or volumetric instability.

Use of curing agents

Another method to achieve shrinkage reduction is by coating the surface layer in a curing agent. This traps the water content by blocking the pores and preventing the escape of moisture.

2. Compensating Shrinkage

Expansion Additives

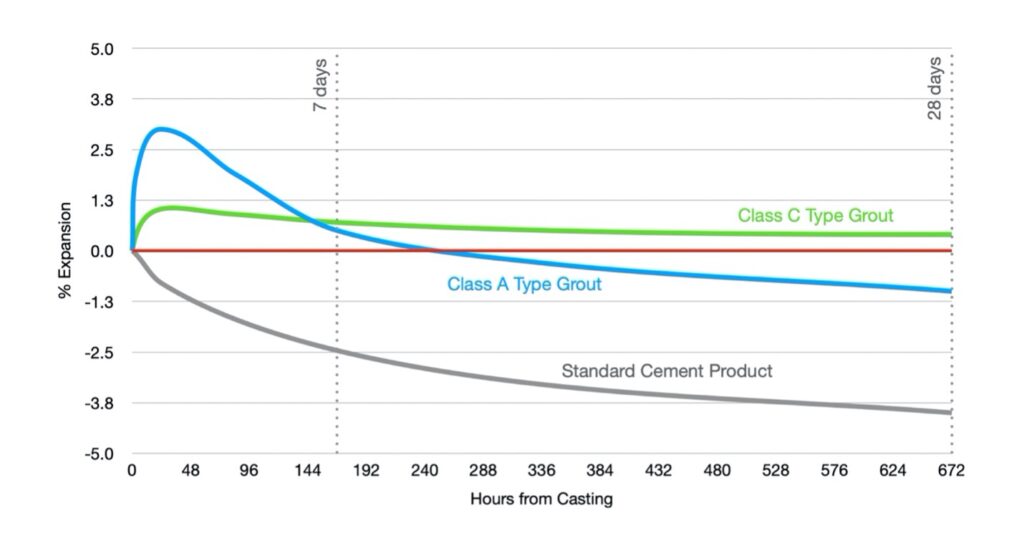

Shrinkage compensating additives are used to minimise cracking and structural movement on the chemical level. The additives work by expanding during either the plastic or drying shrinkage stage to offset the loss in volume. It is critical that the timing of the expansion matches the time of shrinkage to ensure the highest degree of volumetric stability.

3. Designing Shrinkage Within the Structure

Movement Joints and Removing Restraints

Movement Joints and Removing Restraints

Allowing the concrete to move freely throughout its service life is essential. Movement joints can be designed to allow not only for initial curing related shrinkage but also expansion and contraction during the service life. These systems can only be designed effectively if the correct amount of shrinkage is predicted. Refer to the second blog in this series for more details on how to select the right test methods for establishing this as reliance upon AS1012.13 and AS1478.2 alone for example is fraught with danger.

Site Geometry: ‘Engineering the Pour’

Another method we use to allow for shrinkage is through site geometry, or what we call ‘engineering the pour’. The size, shape, surface area and stress concentrations are all variables of shrinkage. Every project is unique in these respects, so we recommend speaking with Bluey about your concerns before placement begins.

Here ends our shrinkage compensation series. If you’d like to know more, please contact the team on 1300 0 BLUEY or email bluey@bluey.com.au.