Is Concrete Repair Worth the Effort?

At Bluey, concrete repair is a major focus of ours. We endeavour to offer solutions to repair concrete rather than let asset owners spend more on a complete replacement project.

One of the common misconceptions with cracked or damaged concrete is that, for the best result, it’s more productive to remove the entire section and replace it with fresh concrete. While this is one option, it’s important to remember that this isn’t the only possible avenue.

Other repair methods include:

- Partial removal and replacement

- Strengthening

- Injection techniques

- Coatings and toppings

In fact, if the infrastructure is used regularly and relied upon by the public, shutting it down is simply not an option.

Why Repair Concrete?

There are three main reasons why we repair concrete.

- Aesthetics – If the defect is highly visible, a client may simply want the concrete to look better. This may be minor surface cracking, mould from water runoff or even the build-up of grime over time.

- Increased Durability of the Structure – If a concrete structure is showing early signs of concrete spalling and corrosion, action should be taken quickly. Taking steps without delay and addressing the issue as it becomes apparent can prevent more widespread and harmful deterioration effects

such as concrete cancer.

such as concrete cancer. - Structural Capacity Increased – If the original concrete did not adequately meet the intended structural requirements repairs can be made to increase the strength and capacity of the concrete. Alternatively, if a structure is being upgraded, widened or expanded, repairing the concrete structurally will increase the load/capacity on the concrete.

.

Where to Use Concrete Repair Products?

Due to the differing applications found in the concrete repair sector, we offer a number of products which are designed to serve unique repair needs. These include:

- General crack injection (BluRez 150, BluRez CSW and BluRez Epoxy 111)

- General structural repairs (BluCem HB50, BluCem HB55 and BluCem LH60)

- Wharf Repairs (BluCem HB50, BluCem HB55 and BluCem HB60)

- Concrete Sealing (BluRez 150, BluRez CSW and BluRez Epoxy 111)

- Sewer Repair (BluCem ZeoGlass, BluSeal AKS, BluRez Epoxy 575 and BluCem HB50)

All products are listed below this article.

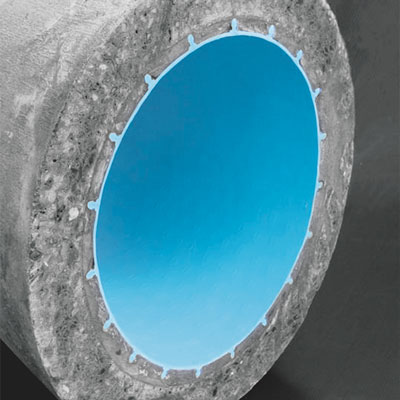

The BluCem HB range is used primarily in concrete repair applications in complex environments such as sewers or around water. These spray-and-trowel applied mortars are specially designed to both solidify the ground as well as reinforce the existing concrete structures.

We use the BluCem HB products where tidal zones create application difficulties or in aggressive environments that contain acid gasses, chloride ions, sulphates or other chemicals which can inhibit product durability.

The BluRez product line is similar but involves resins and epoxies that are injected into concrete cracks. This could be an option on car-park decks or other public assets where disruptions must be kept to a minimum.

Get the Job Done Right the First Time

From tunnels and basements to road construction, railways and ports, we’re committed to providing high-quality products that are designed to do its job the first time.

As well as developing civil engineering products, an important part of our service is on-site technical support. Our team of Civil Engineers are more than happy to inspect a site to determine the validity of a concrete repair job. In our years of experience, we are confident in making a decision that works for all parties and ensures both a safe and non-disruptive project.

Get in touch with the team today at 1300 0 BLUEY or bluey@bluey.com.au