Take a good look at any concrete structure and you’re bound to see a few cracks forming. While it is easy to place the blame on materials or human error, the reality is that it’s in the nature of concrete to crack, even when the utmost care is taken during construction.

When cracks form in concrete, what can be done?

If the cracks are likely to cause structural or durability issues then the best long-lasting solution for cracks may be to replace the compromised section of concrete, however, this method is both costly and time-consuming. Although a larger network of cracks may require a full replacement of concrete, smaller cracks in fewer numbers can be easily and conveniently repaired through crack injection.

What is crack injection?

Crack injection is the process of pumping grout or resin into a void to fill the cavities in a concrete slab. Injection works are typically carried out to aid waterproofing or to prevent corrosion of concrete structures.

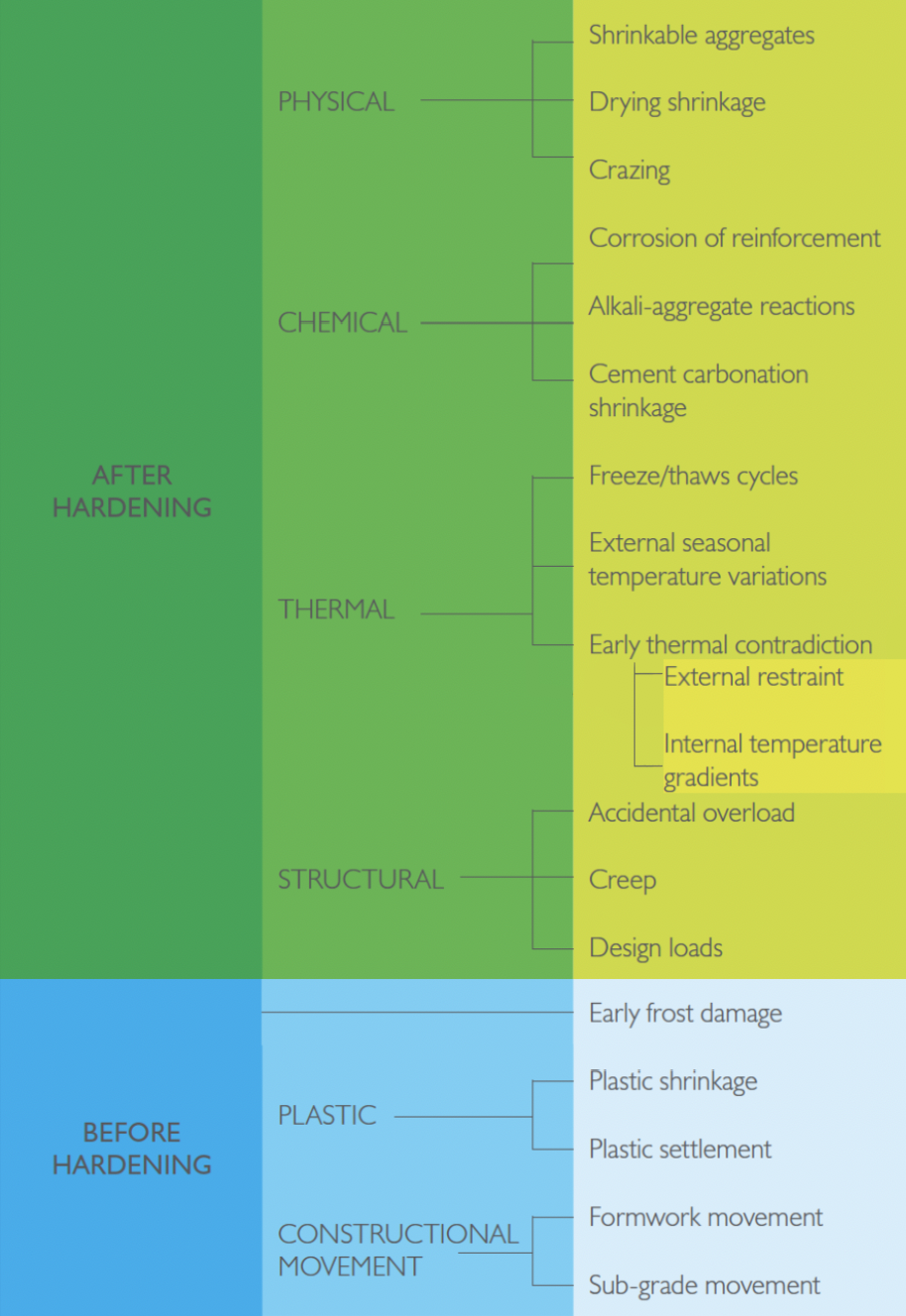

Figure 1: Types of cracks and their causes

The first step is to determine which type of crack is present. These cracks can be broken down into 6 categories which are triggered by a multitude of causes. Figure 1, highlights the relationship between these types of cracks and their causes.

Once you have identified the type of crack, you must then consider all other variables, including:

MOVEMENT OF THE STRUCTURE

Once cracking occurs, movement of the structure takes place at some level. Although this sounds like a major problem, understanding the amount of movement is a key determiner of which injection material to select for repairs. As a rule of thumb, epoxies are stiff and cannot absorb much movement before unbonding. Polyurethane epoxies, however, have greater flexibility and are a preferred epoxy to use for a crack which may be prone to movement. It is important to note that no injection grout will tolerate much movement regardless of elasticity.

WIDTH OF THE CRACK

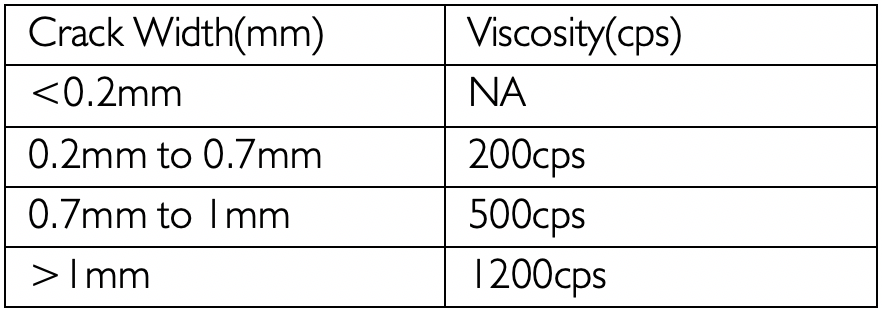

The width of the crack will determine the viscosity required from the injection grout. The viscosity of grout is a measure of its resistance to deformation. The table below shows the viscosity required to accommodate the width of different size cracks.

WETNESS OF THE CRACK

In high flow water infiltration, a fast-reacting polyurethane is ideal to fill the crack. For slower infiltration or ‘damp cracks’ a slower reacting and hydrophilic polyurethane may be the preferred material of choice

Once these factors have been considered you will be in a good position to select the right material for the job. The list below briefly outlines the range of Bluey products and the type of cracks they are suitable for.

BluRez CS150: A hydrophilic polyurethane resin that can be used for sealing wet cracks >1mm.

BluRez 111: A low viscosity epoxy resin suitable for repairing dry structural cracks > 0.2mm.

BluRez CSW: A hydrophobic polyurethane resin that can be used for sealing wet cracks >0.2mm

BluRez 222VL: A low viscosity epoxy resin suitable for repairing dry structural cracks > 0.7mm.

To learn more about the crack injection methods and procedures download the Bluey Crack Repair Procedure PDF or call Bluey today on 1300 0 BLUEY to speak to an expert about your next concrete repair project.